Lensed and Tapered Fibers

LaseOptics specialized in lensed fibers, tapered fibers, shaped fibers for the commercial and research marketplace including laser fiber assemblies, diode lasers coupling, waveguide coupling, MEMS coupling, optical systems and optical communication applications. Our in-depth knowledge and experience with lensed fibers and tapered fibers are customized to the required spot size and mode filed matching. Lensed and Tapered fibers termination combined with excellent service enables us to provide the best possible support for those companies developing applications in the photonics industry. Lensed fibers offer a convenient way to improve coupling between optical fibers and waveguide devices, laser diodes or photo diodes. By laser shaping the fiber end, the light can be transformed to improve mode matching and coupling efficiency with the waveguide device, laser diode chip or photodiode chip

LaseOptics is a lensed fibers manufacturer for biomedical sensor, defense, spectroscopy, research and development, lensed fiber probes and fiber arrays for other applications. Fiber optic probes are a key element for biomedical spectroscopic sensing. We review the use of fiber optic probes for optical spectroscopy, focusing on applications in turbid media, such as tissue. The design of probes for reflectance, polarized reflectance, fluorescence, and Raman spectroscopy is illustrated. We cover universal design principles as well as technologies for beam deflecting and reshaping.

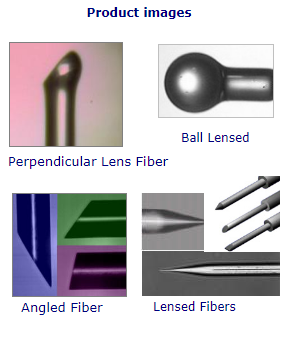

LaseOptics specialized in polarization maintaining lensed fibers with slow axis termination. We manufacture high quality single mode lensed fibers, medical cables, multimode lensed fibers bundles, repairs of any fiber optics cables or patch cords. LaseOptics is manufacturer of high-quality lensed fibers in several shapes like conical lensed fibers and ball lens fibers and double wedge (screwdriver) lensed fiber, shaped etc. and we do Antireflection coating and metallization on lensed fibers, we do make custom lensed and tapered fibers.

LaseOptics offers single mode or multimode fiber bundles with lensed fibers in straight, bifurcated (Y-cable), or lensed fibers arrays fan-out configurations and round or linear bundle end configurations and lensed fibers 2×2 couplers.

Additionally, LaseOptics offers two wavelengths fibers mixed medical multimode lensed fibers bundle and our bifurcated optogenetics cables with connectors of SMA, FC/PC, FC/APC, ST and SC, for other dental and photodynamic therapeutic purposes. LaseOptics lensed fibers are high coupling performance components for collimating, focusing light and improving coupling between optical fiber and laser diode, active devices or photo diodes. The manufacturing processes allow the light to be transformed to improve mode matching and coupling efficiency with the waveguide device, laser diode chip or photo diode chip.

The characteristics of the Lensed Fibers depend greatly upon the applications. For laser diodes and waveguide coupling applications, beam quality is paramount. The focused spot characteristics must match the waveguide characteristics as closely as possible to ensure good coupling. In contrast, lensed fibers to photodiode coupling does not require a high quality beam. Only one must ensure that the focused spot size is smaller than the photodetector. Thus, tapered fiber for photodiode applications can be offered at a much lower cost. LaseOptics lensed fibers technology enables high-end lens to be manufactured in volume at low costs.

Effective and efficient lensed and tapered fiber optic solutions, LaseOptics recognizes that customization is the key to your success. LaseOptics can increase the coupling efficiency of the light by using our lensed and tapered fibers and multimode fiber optic cables.

What is Lensed and Tapered Fibers Coupling Technology?

Lensed and tapered fibers coupling technology refers to a method for efficiently coupling light between two optical fibers or between an optical fiber and another light source, such as a semiconductor laser diode or a waveguide. It achieves this by incorporating specially shaped lenses on the ends of the optical fibers. Lensed fibers coupling technology offers a valuable approach to optimize light transmission between optical fibers and other light sources. By utilizing micro-lensed, it overcomes challenges associated with traditional coupling methods, leading to improved efficiency, easier alignment, and a wider range of design possibilities for various applications. Lensed fibers can be manufactured using a variety of methods, including Etching, melting stretching, Grinding, and Laser processing.

Benefits of Lensed Fibers Coupling Technology:

Improved efficiency: Lensed fiber coupling technology improves the efficiency of light transmission.

Easier alignment: Lensed fiber coupling technology makes it easier to align optical fibers.

Wider design possibilities: Lensed fiber coupling technology offers a wider range of design possibilities for various applications.

Cost-effective: Lensed fiber coupling technology is cost-effective.

Consumes less space: Lensed fiber coupling technology consumes less space, smaller packaging, than bulk optic alternatives.

Lensed and Tapered Fibers Applications Notes:

How do Lensed fibers work? Lensed Tapered fibers work by focusing the light to improve the mode matching between a waveguide and the fiber. Normally we try to get a lens that produces a Gaussian beam. Ideally the Lensed fibers should be made to precisely match the laser diode or waveguide characteristics. Be prepared to supply as much information as possible to help develop the ideal lenses.

which can produce various shapes of optical lensed fiber arrays with low cost and high precision. With the optical fiber lens grinding equipment, can also test the optical spot, far field and other parameters of the lens.

Tapered and lensed fibers offer a convenient way to improve coupling between optical fibers and waveguide devices, laser diodes or photo diodes. By laser shaping the fiber end, the light can be transformed to improve mode matching and coupling efficiency with the waveguide device, laser diode chip or photodiode chip.

Lensed fiber coupling technology is a method for improving the efficiency of light transmission between optical fibers and other light sources. It uses specially shaped lenses on the ends of optical fibers to achieve this.

Key points about this statement:

Diverse fiber types: They are proficient in working with both lensed fibers (with a focused lens at the end) and tapered fibers (gradually narrowing towards the tip).

Customizable shapes: The company can design and manufacture different shapes on the fiber end, beyond just standard lens profiles, to suit unique application requirements.

Custom lensed fiber capability: They offer the ability to create fully custom lensed fibers, tailored to specific customer needs, including the lens shape, size, and other parameters.

Optical Communication Systems: Improves light transmission efficiency in fiber optic communication networks.

Laser Diode Coupling: Efficiently coupled light from a laser diode into an optical fiber for various applications like sensors and optical amplifiers.

Bio-Medical Devices: Used in medical equipment like dental, endoscopes and biosensors for efficient light delivery and signal transmission.

Optical Instrumentation: Enhances light coupling in optical instruments used for spectroscopy, microscopy, and other analytical applications and highly customizable

Type of lens: conical, ball, screwdriver, spherical, angled lens, chisel, and wedged

Type of fibers: SM, MM, Polarization maintaining

Customer determined striped length

With or without AR coating and metallization

High coupling efficiency, easy to use and reliable

Possible applications for such expertise:

Coupling light into waveguides: Precisely shaped lensed fibers can efficiently couple light into small waveguides on chips or other devices.

Diode lasers coupling: Creating custom lensed fibers to optimally match the beam profile of specific laser diodes.

Medical sensing: Designing specialized tapered fiber probes for deep tissue imaging or targeted delivery of light.

Optical microscopy: Utilizing custom lensed fibers to achieve high-resolution imaging with specific focal lengths.

If you require any of the above products, we need this information:

- Shaped-End Tips, like conical, ball, angled, spherical

- Fiber Size (Core, Clad, Buffer)

- What wavelengths are you using

- End Finish (Polish, Cleave, Lens)

- How long should be the Fiber

- Overall Assembly Size

- Fiber Anchoring (Epoxy, Bare, or Other)

- Jacket, Buffer, and Strength Member Materials

- Numerical Aperture (NA) of Fiber

- Termination Type (FC, LC, SC, ST, SMA, Shaped, or Other)

Applications:

- Optical fiber communications

- Optical fiber laser

- Light focusing

- Laser coupling assemblies

- Bio-medical and Dental

- MEMS device connection

- Waveguide packaging

- Optical fiber microparticles sensing

- Connecting optical fibers to semiconductor components

- Photodynamic therapy and Ablation

- Imaging and trapping

- Illuminating small areas

- LD optical amplifiers